- Home

- About Us

- Infrastructure

- Products

- Investor Forum

- Public Offer Documents

- Annual Report & Financials

- Investor Presentation

- Transcript

- Shareholding Pattern

- Press Release

- Policies

- Board & Committee Details

- Contact for Investor

- Media Coverage

- SEBI Circular

- Compliance Under Regulation

- Stock Exchange Fillings

- Annual Return

- Annual Secretarial Compliance Report

- Investor Information

- CSR Report

- Events

- Get in Touch

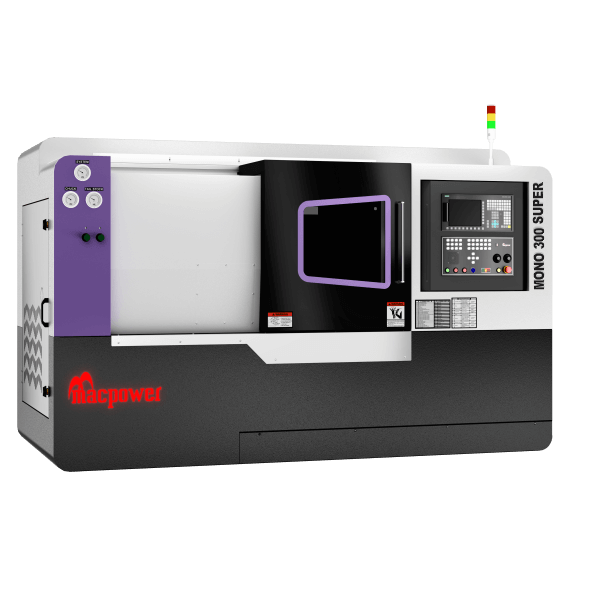

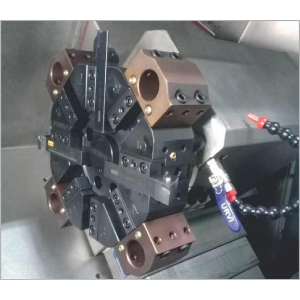

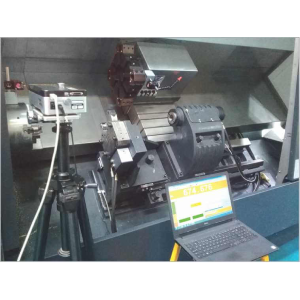

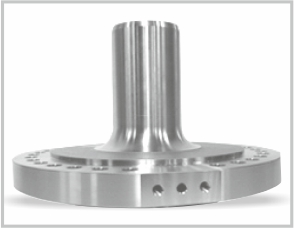

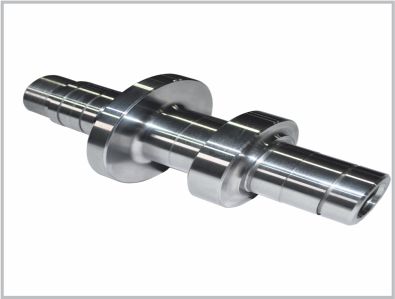

Spindle

Monoblock machines comes with a spindle that has a highly durable and maintenance free feature. Adding further rigidity and stiffness to the spindle assembly comes with three front and two rear angular contact bearing configuration.